Digital Twins: Transforming Construction

Digital twins are revolutionizing the construction industry, offering a virtual representation of physical structures and processes. The integration of these digital replicas enhances efficiency, collaboration, and decision-making throughout the construction lifecycle.

1. Virtual Representation of Real Structures

Digital twins create a virtual counterpart of physical assets, enabling a comprehensive understanding of construction projects. Through advanced simulations and modeling, stakeholders gain insights into the structure’s behavior, performance, and potential challenges, facilitating informed decision-making.

2. Improved Design and Planning

Incorporating digital twins in construction enhances the design and planning phases. Architects and engineers utilize these virtual models to test designs, analyze structural integrity, and assess various scenarios, ensuring optimized designs and efficient planning before physical construction begins.

3. Real-Time Monitoring and Management

During the construction phase, digital twins enable real-time monitoring of progress and performance. IoT sensors and data analytics incorporated into these digital replicas provide live updates on construction activities, allowing for timely adjustments, risk mitigation, and resource allocation.

4. Enhancing Collaboration and Communication

Digital twins foster collaboration among project stakeholders. By providing a shared platform for real-time data and visual representations, they facilitate effective communication and collaboration among architects, engineers, contractors, and clients, streamlining decision-making processes.

5. Predictive Maintenance and Lifecycle Management

Post-construction, digital twins continue to add value by enabling predictive maintenance and lifecycle management. The digital replica serves as a valuable tool for ongoing maintenance, enabling proactive identification of potential issues and efficient management of the structure’s lifecycle.

The adoption of digital twins in construction marks a paradigm shift in the industry, transforming traditional practices into data-driven, collaborative, and efficient processes. As technology evolves, the potential for digital twins to optimize construction projects and ensure long-term sustainability continues to grow.

For a comprehensive exploration of Digital Twins in Construction and their transformative impact, visit Digital Twins in Construction to discover how these digital replicas are revolutionizing the construction industry, enhancing project efficiency, and driving innovation.

5G in Industrial Automation: Transformative Connectivity

5G technology is revolutionizing industrial automation, ushering in an era of enhanced connectivity, efficiency, and innovation across various sectors.

Understanding 5G in Industrial Automation

5G networks offer ultra-fast, low-latency connectivity, vital for real-time communication in industrial automation. This technology enables seamless connectivity between machines, devices, and systems, transforming industrial processes.

As industries embrace the potential of 5G, platforms like 5G in Industrial Automation serve as hubs, highlighting the evolution and impact of this connectivity in industrial settings.

Enhanced Connectivity and Speed

5G’s high bandwidth and low latency enable faster communication and data transfer between machines. This improved connectivity optimizes industrial processes, reducing delays and enhancing productivity.

IoT Integration and Network Slicing

5G facilitates the integration of Internet of Things (IoT) devices in industrial settings. Network slicing allows the creation of dedicated, customized virtual networks, ensuring efficient utilization of network resources for specific industrial needs.

Remote Monitoring and Control

With 5G, industries can remotely monitor and control machinery and processes in real-time. This capability enhances flexibility, allowing for immediate adjustments and interventions, even from distant locations.

Precision Manufacturing and Robotics

5G’s high-speed, low-latency connectivity enables precise control in manufacturing processes. Robotics and automated systems benefit from this precision, optimizing production efficiency and quality.

Safety and Predictive Maintenance

5G supports advanced safety measures and predictive maintenance in industrial settings. Real-time data transmission aids in early detection of potential issues, preventing downtime and ensuring operational safety.

As industries adapt to 5G connectivity, 5G in Industrial Automation platforms provide insights into the integration and impact of 5G technology in industrial automation processes.

Augmented Reality and Training

5G facilitates augmented reality (AR) applications for training and maintenance purposes in industrial environments. AR technology supported by high-speed connectivity enhances training modules and maintenance procedures.

Energy Efficiency and Sustainability

The efficiency of 5G networks contributes to energy conservation in industrial operations. Optimized processes, predictive maintenance, and improved resource allocation lead to sustainable and eco-friendly practices.

Challenges and Adoption

Adopting 5G in industrial automation faces challenges such as infrastructure development, security concerns, and integration complexities. Overcoming these challenges requires collaborative efforts and robust solutions.

Future Prospects and Innovation

The integration of 5G in industrial automation sets the stage for future innovations. Advancements in robotics, AI, and IoT, powered by 5G connectivity, promise transformative advancements in industrial processes.

Exploring platforms like 5G in Industrial Automation unveils the transformative potential of 5G technology in revolutionizing industrial automation, fostering a future of enhanced connectivity and efficiency.

Absolutely, here’s the article:

Industry 4.0: Digital Twins

Introduction to Digital Twins in Industry 4.0

Digital twins represent a revolutionary concept within Industry 4.0, enabling the creation of virtual replicas of physical assets, processes, and systems. These virtual counterparts simulate real-world scenarios, providing insights, predictions, and optimizing operations across various industries.

Digital Twin Technology and Implementation

Digital twin technology relies on sophisticated sensors, IoT devices, and data analytics. By integrating these technologies, organizations can create accurate, real-time models of physical assets. Implementing digital twins aids in predictive maintenance, process optimization, and product development.

Applications in Manufacturing and Production

In manufacturing, digital twins revolutionize processes. They facilitate predictive maintenance by monitoring equipment conditions and predicting failures before they occur. Additionally, they optimize production by analyzing workflows and suggesting improvements to increase efficiency.

Role in Product Development and Prototyping

Digital twins play a crucial role in product development. They allow for virtual prototyping and testing, reducing the need for physical prototypes, thereby saving time and costs. Engineers can simulate product behavior and make adjustments before physical production.

Integration in Smart Cities and Infrastructure

Digital twins extend beyond manufacturing, finding applications in smart cities and infrastructure. They simulate urban environments, aiding in city planning, traffic management, and infrastructure development. They provide insights to optimize resource allocation and enhance overall city functionality.

Challenges and Future Trends

While digital twins offer immense benefits, challenges exist. These include data security, interoperability, and scaling models for complex systems. However, ongoing advancements in AI, IoT, and data analytics aim to address these challenges, paving the way for more robust digital twins.

Digital Twins in Industry 4.0 are revolutionizing how industries operate. To explore the depth of this technology and understand its transformative potential, visit Digital Twins in Industry 4.0 for comprehensive insights.

Feel free to modify or expand upon this article as needed!

Revolutionizing Manufacturing: The Era of Digital Twins

In the dynamic landscape of modern manufacturing, the advent of digital twins has brought about a transformative shift. This technology, which creates virtual replicas of physical systems, is reshaping the way products are designed, produced, and maintained. Let’s delve into the impact of digital twins on the manufacturing industry.

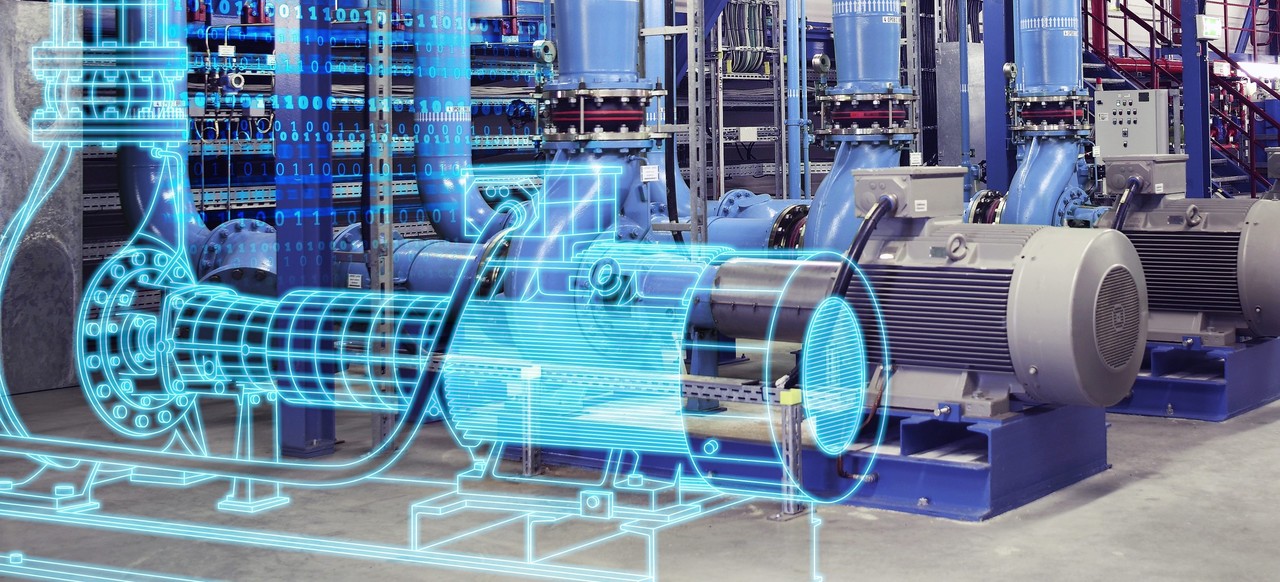

The Essence of Digital Twins

Digital twins are virtual representations of physical objects or systems, meticulously designed to mirror their real-world counterparts. In manufacturing, this technology extends beyond simple 3D models. It involves the integration of real-time data, sensors, and advanced analytics to create a dynamic and responsive virtual replica of a physical asset.

Designing for Success: Digital Twin in the Product Lifecycle

One of the primary applications of digital twins in manufacturing is in product design. By creating a digital twin early in the design phase, manufacturers gain insights into how a product will perform in the real world. This not only enhances design accuracy but also allows for proactive adjustments, reducing the likelihood of costly errors later in the production process.

Optimizing Production Processes

Digital twins play a pivotal role in optimizing manufacturing processes. By simulating the entire production line, manufacturers can identify inefficiencies, streamline workflows, and enhance overall operational efficiency. Real-time data from sensors on the physical equipment is mirrored in the digital twin, providing a comprehensive view for continuous improvement.

Predictive Maintenance for Enhanced Reliability

Incorporating digital twins into manufacturing enables predictive maintenance strategies. By continuously monitoring the performance of physical assets through sensors, digital twins can predict when equipment is likely to fail. This foresight allows manufacturers to schedule maintenance activities proactively, minimizing downtime and reducing overall maintenance costs.

NeverEmpty’s Cutting-Edge Digital Twin Solutions

In the realm of digital twins in manufacturing, NeverEmpty stands out as a provider of cutting-edge solutions. NeverEmpty’s digital twin technology goes beyond traditional applications, offering a comprehensive suite of tools for design optimization, process simulation, and predictive maintenance.

Explore NeverEmpty’s Digital Twins in Manufacturing solutions here.

Enhancing Collaboration and Communication

Digital twins facilitate enhanced collaboration among teams involved in the manufacturing process. Designers, engineers, and production managers can work collaboratively within the digital twin environment, fostering better communication and synergy. This collaborative approach results in faster decision-making and more agile responses to challenges.

Real-Time Monitoring and Analytics

The integration of real-time data into digital twins allows for continuous monitoring of manufacturing processes. This data-driven approach provides valuable insights into performance metrics, quality control, and resource utilization. Manufacturers can leverage analytics derived from the digital twin to make data-driven decisions that optimize efficiency and output quality.

Supply Chain Optimization

Digital twins extend their influence beyond the factory floor, impacting supply chain management. Manufacturers can create virtual replicas of their supply chain networks, enabling better visibility and control. This enhanced oversight facilitates more accurate demand forecasting, inventory management, and logistics planning, ultimately reducing costs and improving overall supply chain resilience.

Addressing Sustainability Challenges

Digital twins contribute to sustainability efforts in manufacturing. By optimizing processes, reducing waste, and minimizing energy consumption through simulation and analysis, manufacturers can make significant strides in environmental responsibility. Digital twins provide a platform for experimenting with eco-friendly initiatives without risking disruption to physical operations.

Embracing the Future of Manufacturing with Digital Twins

As manufacturing continues to evolve, digital twins emerge as a key enabler of innovation and efficiency. Embracing this technology allows manufacturers to stay ahead of the curve, providing a competitive edge in an increasingly complex and dynamic industry. With NeverEmpty’s advanced digital twin solutions, the era of smart, connected manufacturing is within reach, promising a future where efficiency, reliability, and sustainability converge.

Revolutionizing Supply Chains: Introduction

In the realm of logistics, the integration of robotics is heralding a transformative revolution. This article delves into the profound impact of Robotics in Logistics, exploring how automated systems are reshaping supply chains, optimizing processes, and paving the way for a new era of efficiency and precision.

To explore the latest trends and innovations in Robotics in Logistics, visit Robotics in Logistics. This platform offers insights into how businesses leverage robotics to enhance their logistics operations and navigate the complexities of modern supply chains.

Automated Warehousing: The Rise of Robotic Systems

The heart of logistics lies in efficient warehousing, and here, robotics takes center stage. Automated guided vehicles (AGVs) and robotic arms collaborate seamlessly to handle tasks like picking, packing, and sorting. This not only accelerates the pace of operations but also minimizes errors, creating a more streamlined and reliable warehousing process.

Optimizing Order Fulfillment: Speed and Accuracy

Robotics in logistics introduces unparalleled speed and accuracy to order fulfillment processes. Automated systems can swiftly locate, pick, and pack items for shipment, significantly reducing order processing times. This speed not only meets the demands of today’s fast-paced markets but also enhances customer satisfaction through timely and precise deliveries.

Last-Mile Delivery Solutions: Drones and Autonomous Vehicles

The last mile of delivery has long been a logistical challenge, but robotics is changing the game. Drones and autonomous delivery vehicles equipped with robotic systems navigate urban landscapes, delivering packages with efficiency. This innovation in last-mile logistics not only reduces delivery times but also addresses congestion and environmental concerns.

Inventory Management Precision: Robotic Auditing and Tracking

Maintaining accurate inventory levels is crucial in logistics. Robotics contributes to inventory management precision through automated auditing and tracking systems. Drones equipped with cameras and sensors can perform aerial inventory checks, ensuring that stock levels align with digital records. This level of accuracy minimizes discrepancies and prevents stockouts or overstock situations.

Collaborative Robotics (Cobots): Human-Robot Collaboration

Collaborative robotics, or cobots, exemplify the harmonious integration of human and robotic labor. In logistics, cobots work alongside warehouse personnel, assisting in tasks that require strength and precision. This collaboration not only enhances efficiency but also creates a safer and more ergonomic working environment for human workers.

Predictive Maintenance: Ensuring Continuous Operations

Robotics in logistics introduces the concept of predictive maintenance. Automated systems can monitor the health of robotic components and predict potential issues before they lead to downtime. This proactive approach ensures continuous operations, minimizing disruptions in logistics processes and maximizing overall efficiency.

Data-Driven Decision-Making: Insights for Optimization

The integration of robotics generates vast amounts of data in logistics operations. Analyzing this data provides valuable insights for optimization. Machine learning algorithms can identify patterns, forecast demand fluctuations, and suggest strategic adjustments to logistics processes. This data-driven decision-making ensures that logistics operations are not just efficient but also adaptive to changing circumstances.

Enhanced Safety Measures: Robotic Precision and Caution

Safety is a paramount concern in logistics, and robotics brings an extra layer of precision and caution. Automated systems are equipped with sensors and advanced algorithms to navigate through environments without causing harm. This enhances workplace safety, minimizes accidents, and ensures the smooth coexistence of humans and robots in logistics spaces.

Cost-Efficiency and Scalability: Long-Term Benefits

While the initial investment in robotics may seem significant, the long-term benefits in terms of cost-efficiency and scalability are substantial. Automated systems can operate around the clock, minimizing labor costs and increasing operational scalability. As technology advances, the return on investment in robotics becomes even more evident.

The Future Landscape: Evolving Logistics with Robotics

The journey of Robotics in Logistics is an ongoing evolution. As technology continues to advance, we can expect further innovations in robotic capabilities, increased integration with artificial intelligence, and a broader range of applications in logistics. The future promises a logistics landscape where efficiency, precision, and adaptability are not just goals but inherent qualities powered by robotics.

Conclusion: Navigating the Future with Robotic Precision

Robotics in Logistics is more than a technological trend; it’s a fundamental shift in how we approach the complexities of supply chains. From automated warehousing to last-mile delivery solutions and predictive maintenance, the impact of robotics is reshaping logistics for the better. As businesses embrace these innovations, they navigate the future with robotic precision, unlocking new levels of efficiency and agility in the dynamic world of logistics.

- Total visitors : 10,923

- Total page views: 13,249

Categories

Recent Posts

- Top Benefits of Buying Your Bed Online vs. In-Store

- The ultimate guide to birthday catering for stress-free celebrations

- Selecting the Ideal Birthday Caterer: Essential Considerations for an Amazing Celebration

- What are the critical details the parents need to understand about the pediatric gastroenterology?

- Branding That Works: Safety Vests, Custom Hi-Vis, And Beer Cooler Bags That Keep You Noticed

- Pros and Cons of .io Domain Name Extension

- How IT Consulting Companies in Los Angeles Help Drive Business Growth and Innovation?

- Swim with Confidence: Why One North Swimming Lessons Are Perfect for You

- 10 Unique Food Business Startup Ideas to Ignite Your Culinary Dreams

- The Impact of VPS Hosting on Your Website’s SEO

- Event Planning and SEO: Making Your Business Visible Online

- Streamlining Reservations and Appointments

- The Backbone of Connected Devices

- Digital Transformation in Government

- Terobosan Terbaru dalam Teknologi Smartphone

- iPhone 15 Inovasi Terbaru dari Apple

- Defining SaaS Companies

- Defining SaaS Companies

- 6 Best Timesheet Management Software for 2024

- How Employees Can Use Employee Monitoring Software to Their Advantage?

- Remote Work Success: How to Create a Mobile Office for Business Trips

- Budget-Friendly Brilliance Best Smartphone Options

- Green Waste-to-Energy Solutions for Sustainability

- Powering the Future Megawatt Electrolyzer Innovations

- Pinnacle of Technology Best Cellphone Choices 2022

- Introducing the Latest New Samsung Phone 2022 Unveiled

- Elevate Your Style Samsung Galaxy 4 Watch Unveiled

- Elevate Your Lifestyle with Apple Watch 7 Cellular

- Elevate Your Mobile Experience with Verizon’s Samsung Phones

- Elevate Your Experience Samsung Galaxy Z Fold3 Unveiled

Archives

- February 2025

- January 2025

- December 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- February 2024

- January 2024

- December 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- July 2019

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

Partner

ecommerce web design dubai

ecommerce website development dubai

ecommerce website dubai

ecommerce development in dubai

ecommerce development company dubai

ecommerce development company in dubai

ecommerce development dubai

ecommerce website development companies in dubai

ecommerce website development company in dubai

ecommerce website development in dubai

ecommerce website design company near me

ecommerce website design company dubai

ecommerce web development dubai

web ecommerce development

ecommerce website in uae

ecommerce website design dubai

ecommerce web design agency

Partner

app design Dubai

app developers in dubai

app development companies in dubai

app development dubai

application development dubai

app developers uae

app development companies in uae

app development uae

mobile App designer Dubai

mobile App Development Company Dubai

mobile app development company in dubai

mobile app development dubai

mobile application dubai

mobile app development company in uae

mobile app development uae

mobile application development uae

mobile app development company